How Modified Atmosphere Packaging (MAP) Protects Food From Spoilage

Food and beverage businesses often look for improved ways to package perishable goods. Proper packing techniques increase product shelf life, preserve freshness, ensure flavor, and prevent discoloration. One method to achieve these objectives is modified atmosphere packaging. Below, you can learn more about MAP and how nitrogen can improve its results.

Understanding MAP With Nitrogen

There are several methods for extending food and beverage shelf life, but some are more effective than others. Combining MAP processes with the use of food-grade nitrogen allows organizations to optimize preservation methods.

What Is MAP?

MAP is the practice of manipulating perishable packaging atmosphere to increase product longevity. It reduces the contained oxygen volume in packaging to prevent aerobic spoilage and microorganism formation.

This process also prevents water vapor formation and replaces oxygen with other gases in the packaging to deliver additional product benefits, such as maintaining quality and extending shelf life. Businesses use MAP to enhance product image, nutrition appeal, and texture. This process does not rely on chemicals, often making it more appealing to consumers.

The Role of Nitrogen in MAP

Nitrogen, compared to other atmospheric gases like carbon dioxide and oxygen, can create an ideal environment for food products. This gas has inert properties, meaning it poses no threat to food safety or quality. With these properties, nitrogen has revolutionized food preservation. Food and beverage businesses leverage nitrogen gas for processing, packaging, and storage.

Commercial food production businesses utilize food-grade nitrogen generators to improve product shelf life with packaging techniques. Proper packaging reduces oxidation processes and prevents contamination, boosting item longevity. Other benefits of nitrogen include:

- Flavor preservation: Nitrogen reduces moisture loss and protects products from contamination to preserve flavor.

- Reduced spoilage: Utilizing food-grade nitrogen inhibits oxidation and prevents moisture loss to keep food components from degrading.

- Texture uniformity: By preventing oxidative damage, reducing moisture loss, and protecting products from physical collapse, nitrogen allows products to maintain uniform textures.

- Limited microbial growth: This gas slows microbial growth by reducing the oxygen these microorganisms need to survive.

Nitrogen Techniques for Food and Beverage

There are several ways to embrace food-grade nitrogen for perishable products. Consider these nitrogen displacement techniques:

- Nitrogen flushing: Flushing refers to cleansing processes. Nitrogen flushing aims to remove contaminants to achieve desirable conditions. This technique focuses on product quality, system cleanliness, and process efficiency.

- Nitrogen purging: Purging creates a controlled environment by removing or displacing reactive gases like oxygen. This technique ensures product quality by preventing oxidation and contamination.

- Nitrogen blanketing: Nitrogen blanketing prevents oxygen from entering by maintaining nitrogen gas in a container or over a product’s surface. This technique is beneficial for storage and processing where protection from degradation is crucial.

Applications of MAP and Nitrogen in the Food and Beverage Industry

Implementing MAP and food-grade nitrogen is beneficial for various perishable products. Common applications include:

- Baked goods: Nitrogen preserves textures and flavors by reducing oxidative reactions.

- Processed dairy: Nitrogen allows dairy products like cheese to maintain appetizing colors and consistency.

- Fresh fish and meat: Nitrogen ensures these products remain bright pink or red to create a visual cue of freshness for consumers.

- Produce: Nitrogen allows fruits and vegetables to maintain freshness.

- Carbonated beverages: Nitrogen allows these beverages to maintain carbonation and flavor.

- Wine and beer: Nitrogen blankets can create a protective layer over storage tanks to protect beverages like wine and beer from oxygen contact.

- Coffee: Reinforcing coffee bags with nitrogen helps preserve the freshness of the beans or grounds, protecting them during transportation and storage.

- Snacks: Snacks like potato chips, nuts, and pretzels often employ MAP and nitrogen to prevent oxidation and maintain shelf life.

Nitrogen Flushing for Optimal MAP Results

Nitrogen flushing is particularly useful for MAP processes as this technique prepares packaging. The initial oxygen removal process is crucial, and nitrogen flushing is one of the most effective ways to accomplish it, especially in large-scale operations.

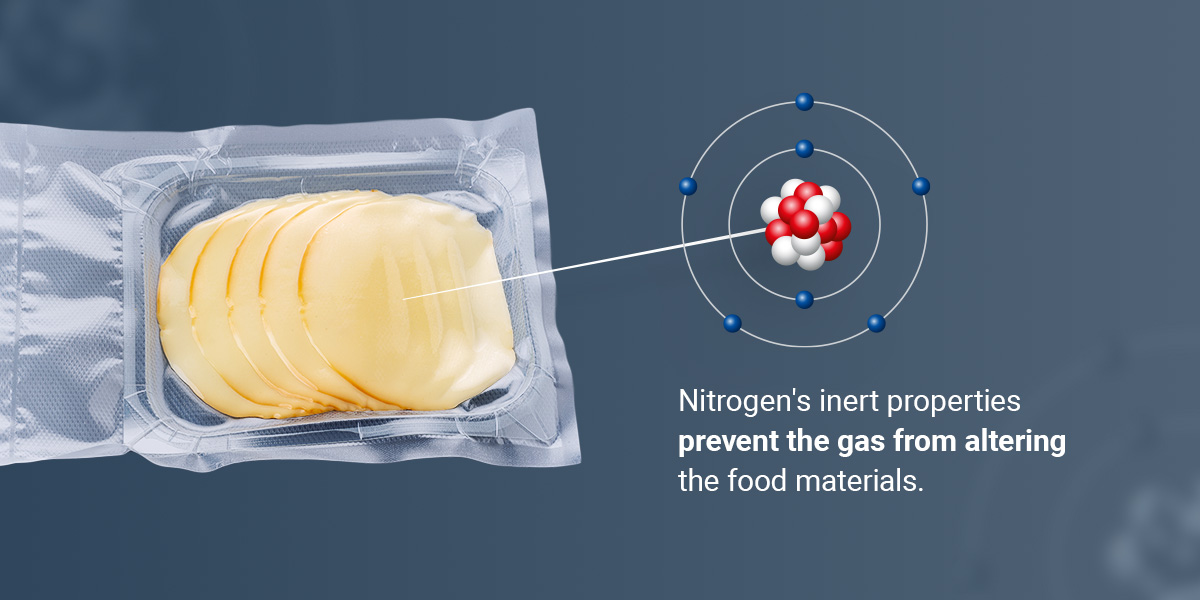

This process removes oxygen and impurities from within the food packaging while filling it with nitrogen gas. Nitrogen’s inert properties prevent the gas from altering the food materials. They inhibit the growth of microorganisms and prevent oxidative processes.

Nitrogen Flushing Validation

It is important to validate nitrogen flushing processes and ensure accurate oxygen level monitoring. Flushing validation should be part of your quality assurance processes and adhere to regulatory requirements. You can leverage several types of equipment and strategies to monitor oxygen levels and verify flushing. Examples include:

- Oxygen sensors: Measure oxygen levels inside a package with a small needle.

- Headspace gas analysis: Determine the package’s gas composition by drawing a sample from the sealed package.

- Package leak detection: Ensure airtight packages with leak detectors.

- Gas purity monitoring: Measure the purity of nitrogen gas to ensure regulatory compliance.

Nitrogen Generators and MAP Technology

Nitrogen generators are ideal for implementing MAP and nitrogen techniques. These systems separate nitrogen and oxygen molecules to supply on-demand pure nitrogen. Having an on-site generator also eliminates the need for third-party nitrogen suppliers, allowing you to save costs and reduce operational downtime.

Liberty Systems’ Nitrogen Generators for MAP

At Liberty Systems, you can find nitrogen generators that provide consistent nitrogen purity. We offer two generator styles — membrane-based and pressure swing adsorption (PSA) systems. Our membrane-based systems are cost-effective and meet demands for applications with 99.9% purity requirements or lower.

PSA systems offer up to 99.999% purity levels, ensuring a cleaner and high-capacity nitrogen flow. Along with saving costs, eliminating the need for tank rentals, and ensuring on-demand nitrogen, Liberty Systems delivers additional peace of mind by providing up to a three-year warranty coverage program.

Nitrogen Purity Standards for MAP

Nitrogen is common in the food and beverage industry, but it is crucial to note the importance of using food-grade gas. Food-grade nitrogen has a 99% or above purity level, meeting regulatory compliances and aiding in quality control. Higher purity levels indicate lower levels of contaminants such as moisture and other gases.

Along with preventing product compromise, food-grade nitrogen will not impact the taste, appearance, or smell of products. It also undergoes strict quality control procedures during production and handling, ensuring the gas is safe for food use.

Comparing MAP to Other Preservation Methods

While other preservation methods exist, MAP processes are often ideal for a broader range of applications. Consider how MAP compares to other common techniques.

MAP vs. Inert Gas Blanketing

Inert gas blanketing is another method for protecting perishables from oxidation, contamination, or moisture. However, rather than modifying the package atmosphere, this method creates a protective layer around the product. It is more common for storing liquids in tanks or other containers rather than food products. Inert gas blanketing is more suitable for bulk storage applications of products like oils, sauces, powdered milk, and flavorings.

MAP vs. Vacuum Packaging

Vacuum packaging involves removing most air from a package and sealing the package to collapse it and maintain the vacuum. This method protects perishables from oxidation and prohibits moisture buildup. However, it is impossible to create a complete vacuum, meaning at least some oxygen will remain in the package.

Because vacuum packaging collapses packages, it is best to use this method when appearance is not a concern. Meats and cheese can rely on vacuum packaging, but an ideal application is preventing freezer burn in frozen foods.

Embrace the Benefits of Food-Grade Nitrogen With Liberty Systems

Liberty Systems has been pioneering nitrogen solutions since 2004. With a commitment to quality standards and tailored solutions, you can feel confident in our ability to create value for your business needs. Reach out with any questions or to request a quote.