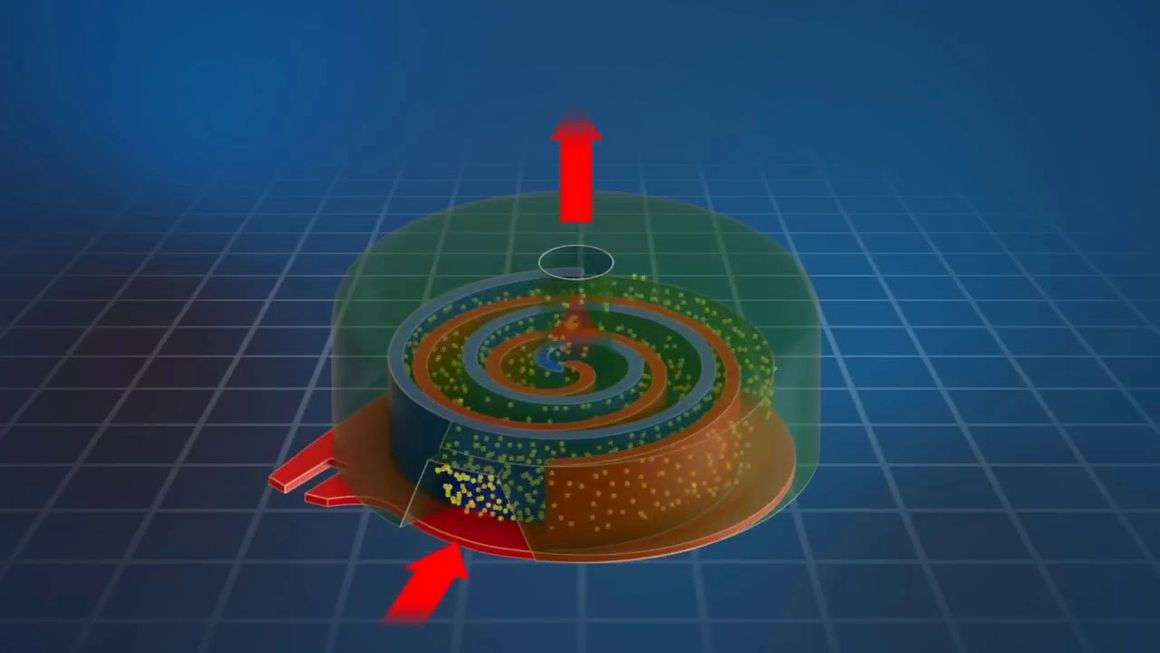

Rotary Scroll Air Compressors

Scroll compressors fall under the displacement compression category of air compressors. In displacement compression, the air is sucked into the compression chambers and trapped to reduce its volume. Scroll air compressors can generate pressures of 100 to 150 psi in single-stage units. Liberty Systems offers high-quality scroll air compressors for various industrial applications.

What Is an Oil-Free Scroll Air Compressor?

Like rotary screw air compressors, there are also different types of scroll compressors. One is the oil-free variant, known for producing clean air. Air compressors with oil-free mechanisms are suitable for high-purity air applications.

Oil-free scroll compressors generate continuous airflow through multiple stages without requiring oil lubrication. Liberty Systems offers the Hertz Oil-Free Scroll Compressor for customers looking for premium, name-brand equipment for their operations.

The Hertz oil-free scroll compressor features easy-to-use controllers that allow users to run up to eight oil-free scroll compressors simultaneously. Our HS Series scroll compressors deliver 100% oil-free compressed air, making them ideal for the food and beverage, medical, dental, electronics and transportation industries.

Benefits of Oil-Free Scroll Compressors

Rotary scroll air compressors are efficient instruments that offer plenty of benefits. Oil-free compressors:

- Eliminate contamination: Oil-free compressors are ideal for sensitive applications because they introduce zero oil contamination during the manufacturing process.

- Are highly efficient: Scroll compressors are 10 to 15% more efficient than reciprocating compressors. Because scroll compressors don’t have discharge valves, there’s less airflow resistance, which helps increase efficiency.

- Are energy-efficient: Scroll compressors consume up to 25% less power, translating to lower energy costs and more savings for the company.

- Are low maintenance: Because scroll compressors have few moving parts, they also have a low chance of mechanical failure. Additionally, the oil-free mechanism eliminates the need for frequent oil changes, translating to less downtime and maintenance.

- Have low vibration and sound levels: Having fewer moving parts in oil-free scroll compressors means they generate less vibration and noise during operation.

- Have a compact design: Scroll compressors generally have a compact, lightweight design, especially when compared to rotary compressors. The small footprint is beneficial for quick installation and space-constrained facilities.

Request a Quote for a Scroll Air Compressor Today

Liberty Systems provides reliable clean dry air solutions to customers in a wide range of industries. We carry a selection of high-quality air compression and nitrogen generation systems designed to meet industry standards. We are the preferred high performance clean dry air solution partner in laser cutting. We take pride in having in-house trained technicians traveling throughout North America to provide customers with technical support for our systems. If you’re looking for dependable manufacturing solutions, contact Liberty Systems today to request a quote.